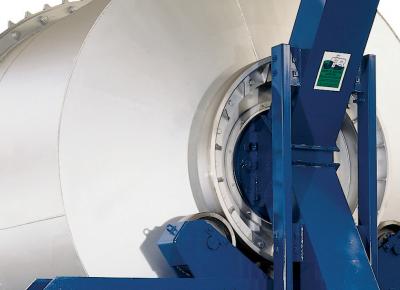

Rotary Drum Mixers

The Rotary Drum Mixer is a quick, efficient, and the ideal gentle industrial mixer with a low speed and no moving parts inside the drum. JR Boone's rotary drum mixers are used all over the world for tea blending, often with optional spray bar for liquid additions. Rotary Drum Mixer is also perfect for delicate, friable or abrasive materials.

The unique mixing blades are fully welded to the rotating drum and completely fluidise the mixture with every revolution, the combination of low speed and no moving parts within the drum mixer produce a no shear, gentle mixing action. Within the fluidised mixture powders and granules of widely different bulk densities and particle size can move freely ensuring a rapid and efficient mix.

Available in 14 standard batch sizes from 50L to 25,000L, continuous, lab size and non-standard versions are also produced to match your specification. A wide variety of options are available or we can design your industrial drum mixer around the needs of your process.

The Rotary Drum Blender / Mixer is highly efficient and simple to operate, see the benefits:

- Quick Mixing: Short length to diameter ratio for quicker end to end mixing

- Gentle Mixing: The fixed contra flow blades lift and quickly transfer the fluidised product around the mixer

- Efficient. The fluidised ingredients ensure highly efficient mixing of trace and minor additions

- Low power: Low rotational drum speed and the minimum number of mixing blades reduce power requirements

- Complete discharge: all the fluidised contents are discharged via the combined inlet and outlet

- Safety and easy to clean: The totally enclosed mixing drum is easily inspected or cleaned via a large access door fitted with a code key interlock

- Hygienic design: No corners for material to adhere to

- Low costs; Minimum power requirements and maintenance free operation for longer periods of continuous running

Adhesive granules

Titanium dioxide

Soap powder

Detergent powder

Pot pourri

Cocoa powder

Heart tablets

Spices

Tea

Coffee granules

Activated carbon

Carpet fibres

Rice flakes

Floor screeds

Bauxite

Rubber compound

Pigments

Confectionery

Resins

Gelatine

Muesli

Coated fish foods

Dried vegetables

Metallic powders

Welding Flux

Glass frit

Grass seeds

For more information please call: ++44 (0) 1260 272894

Or email sales@jrboone.com